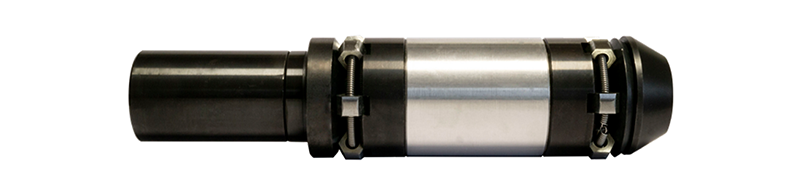

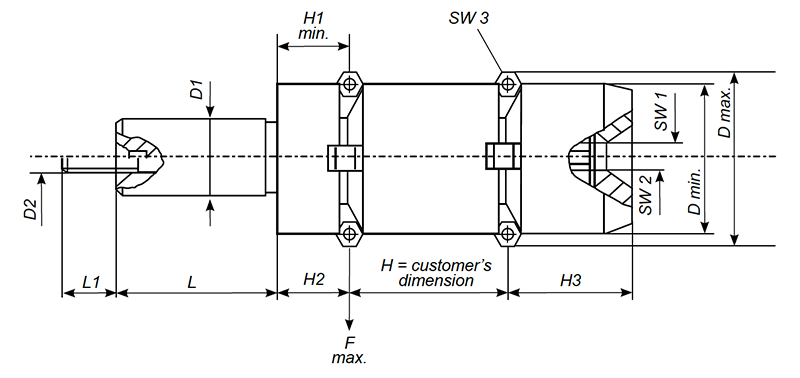

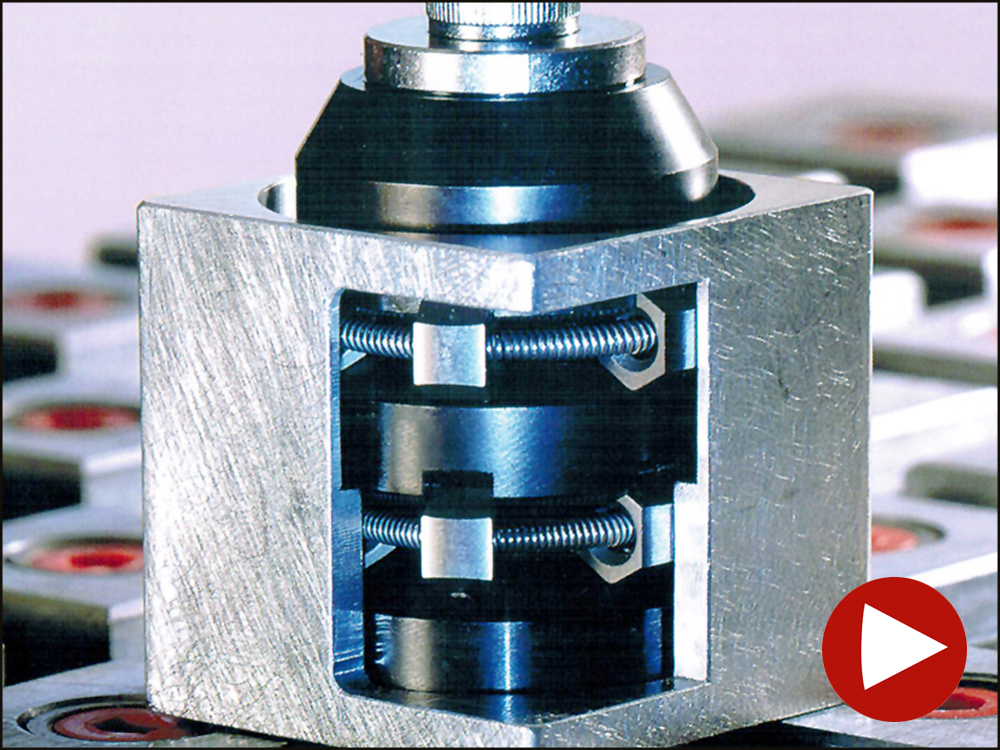

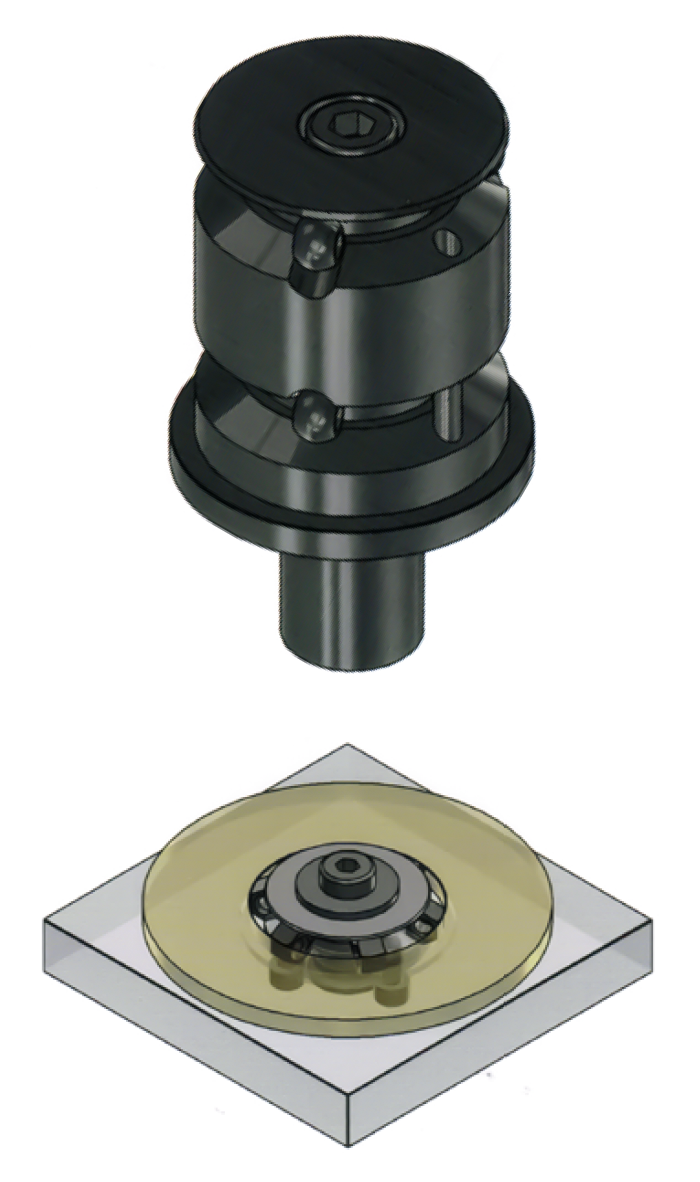

Multi-level centering clamp

For both automatic and manual clamping

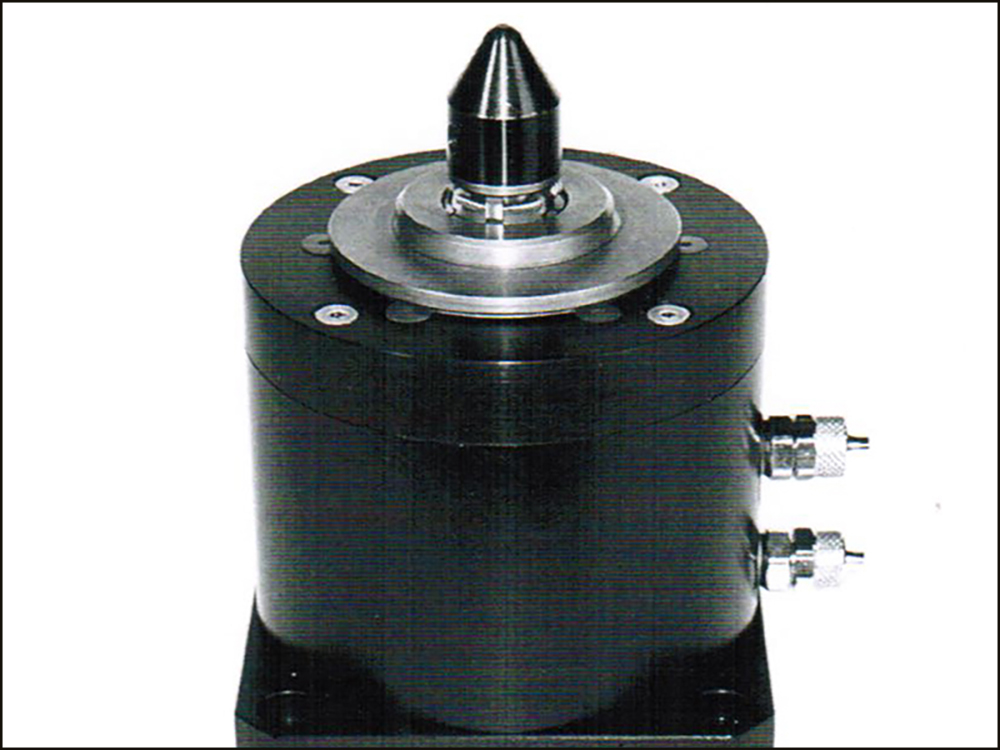

Multi-level centering clamp

For both automatic and manual clamping

Benefits:

- Varying diameters

- Floating clamping levels

- Two or any number of clamping levels

- Precise self-centering

- Stable connection

- Clamping with a draw-down effect

- Distortion-free positioning and clamping

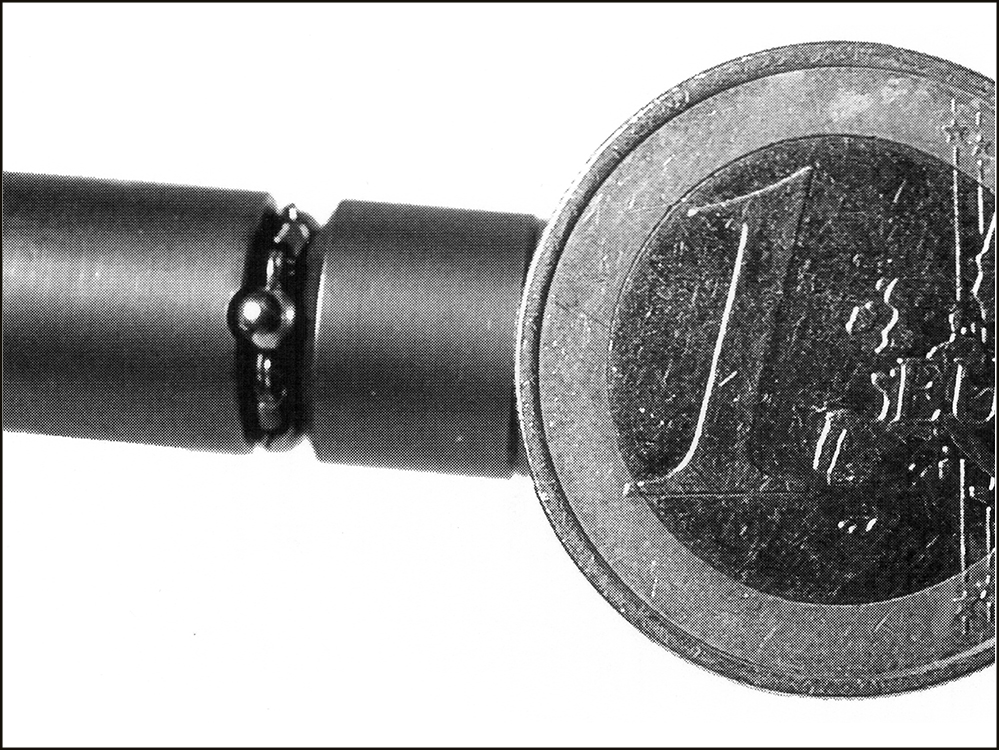

- Suitable for smaller bore holes of 12 mm and up

- Any installation position

- Generous clamping range

- Minimizes tolerances by positioning and clamping at the zero point

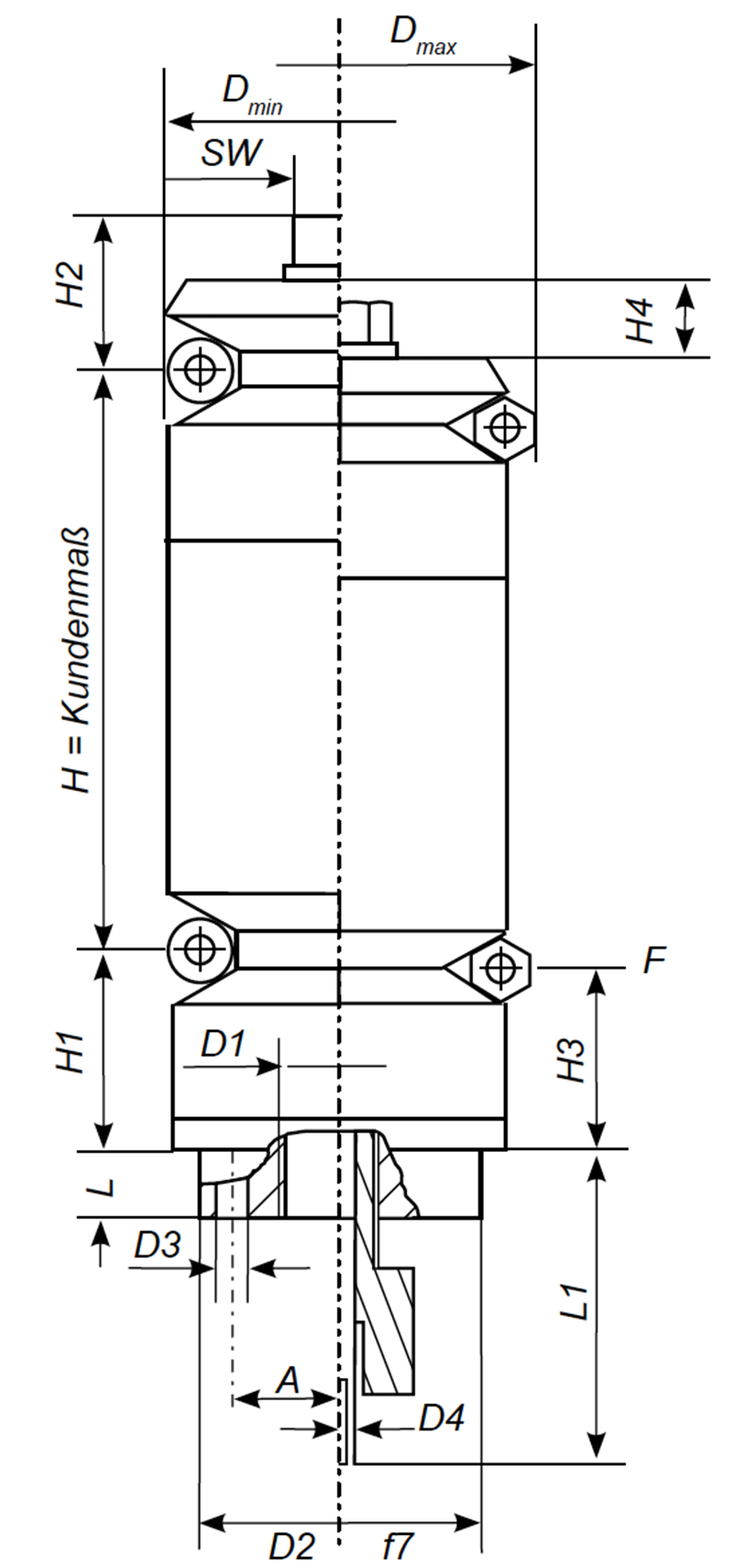

- Customized height according to customer’s dimensions

Material:

Body: 1.2842, hardened and burnished

Ball/segment: 1.4112, hardened and ground

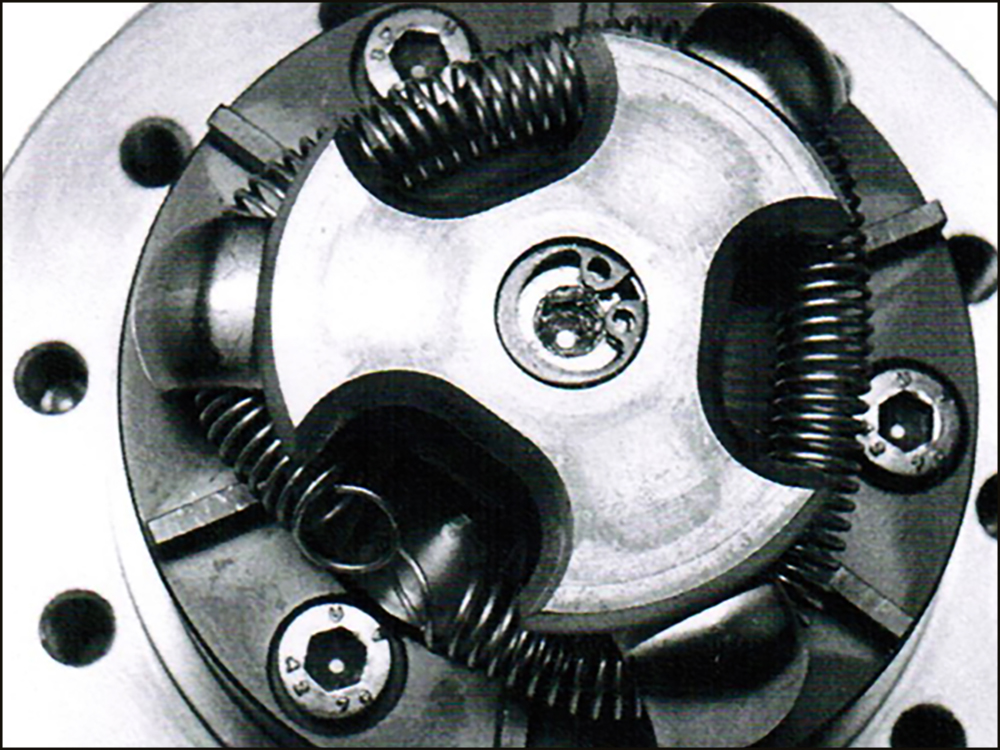

Tension spring: 1.4210 (VA)

Applications:

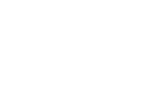

Friction-locked clamping for milling, turning, welding, bonding, assembly and transport, etc. Can be operated from above or below, even in blind holes.

With segments to protect the workpiece or with balls, e.g. for tapered and cast workpieces. Segments and balls can be combined. The high level of stability allows for vibration-free all-around machining without any supplementary tension.

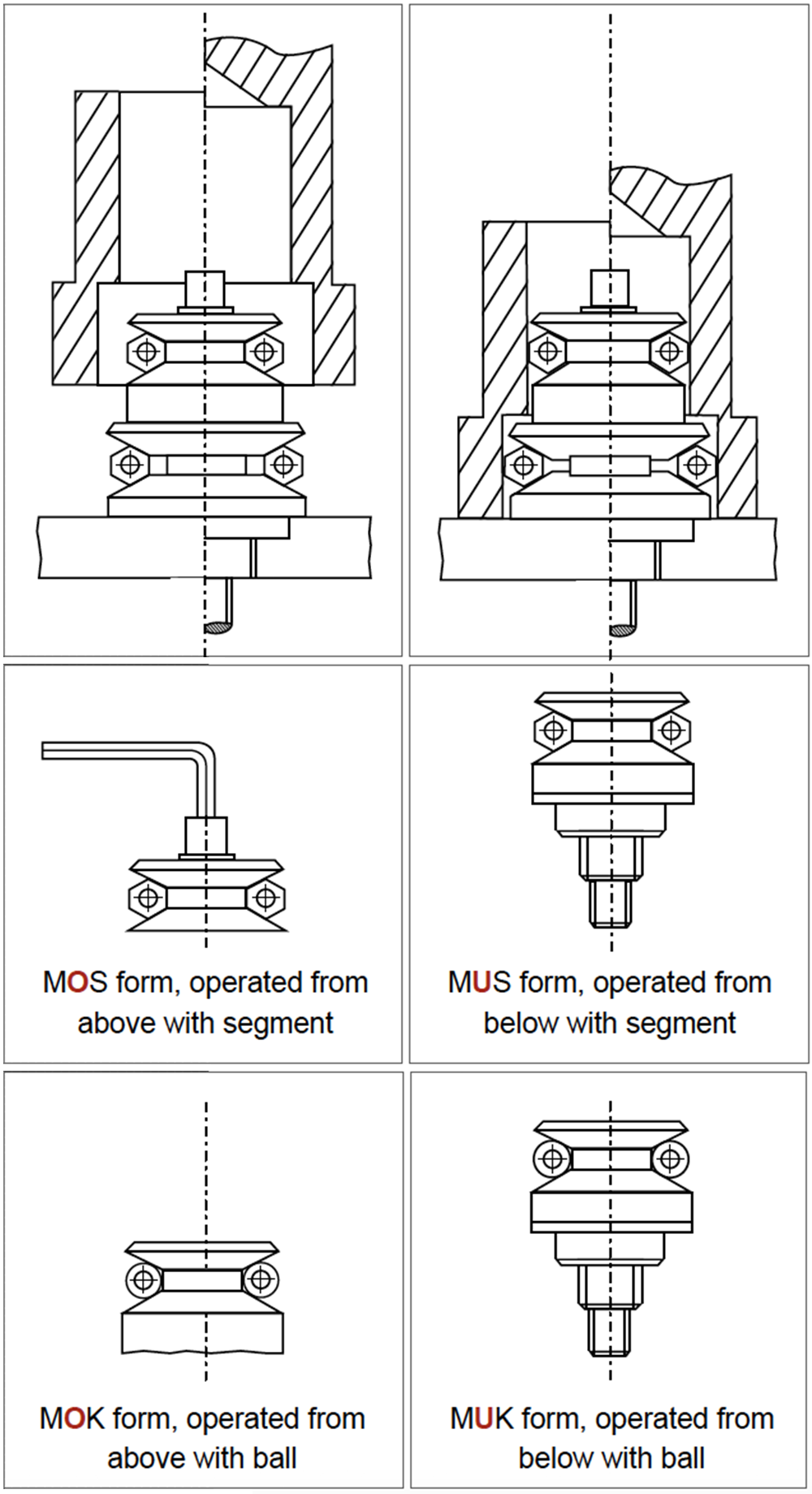

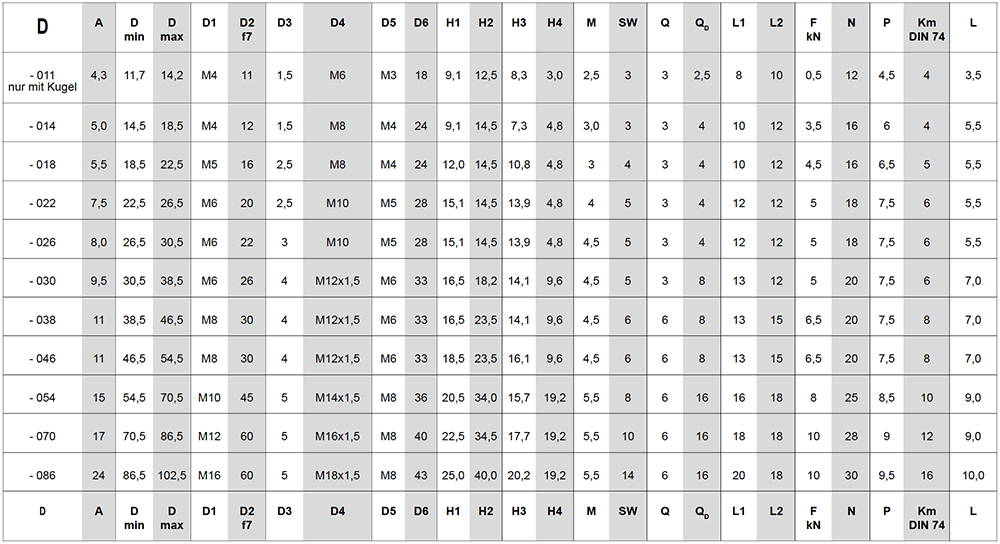

(please click on the table to enlarge)

Q = number of balls, QD = diameter of balls

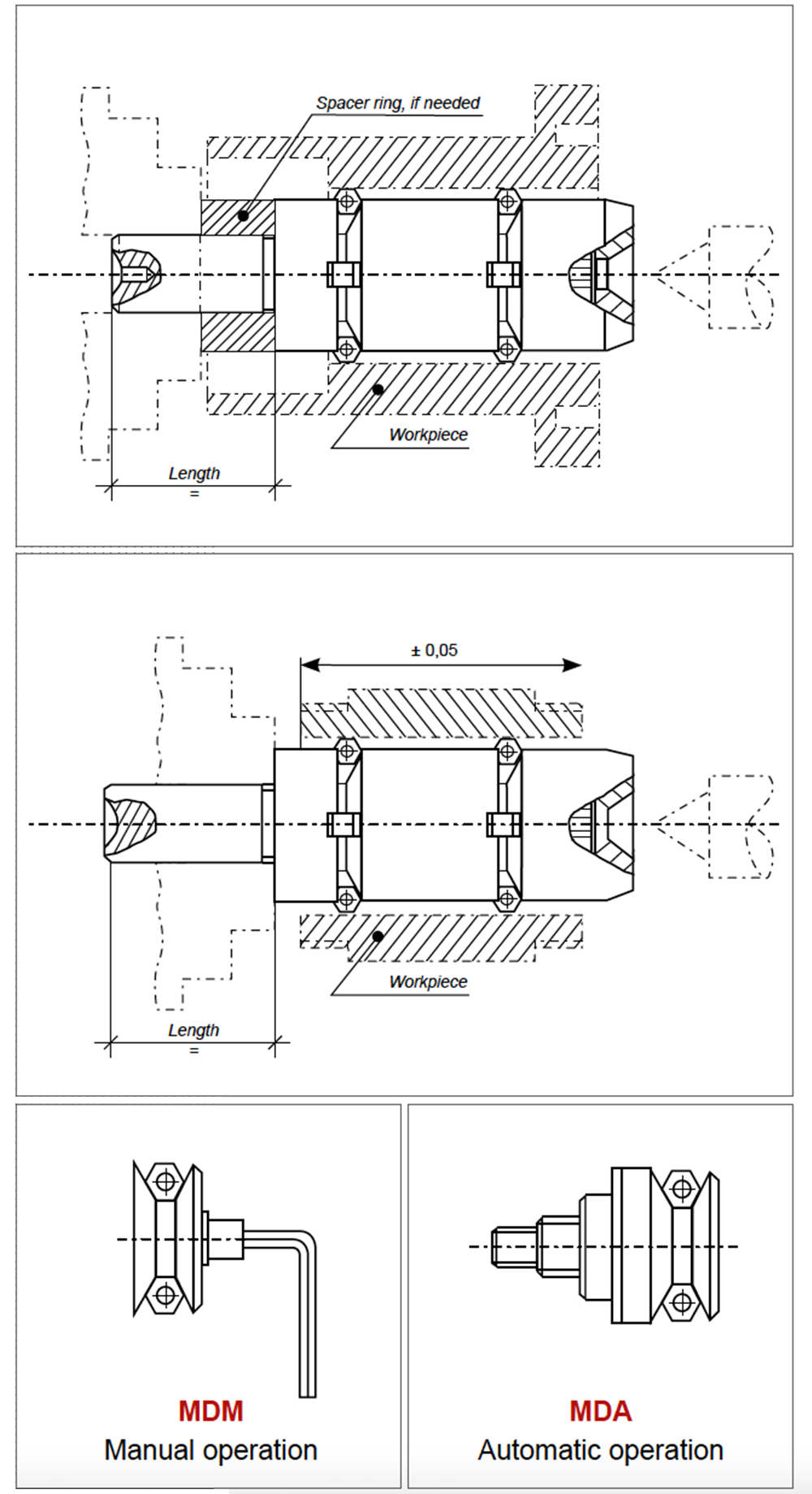

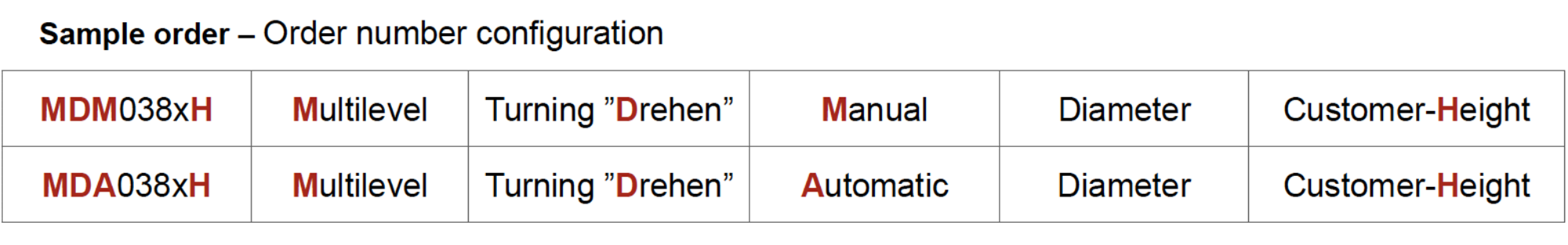

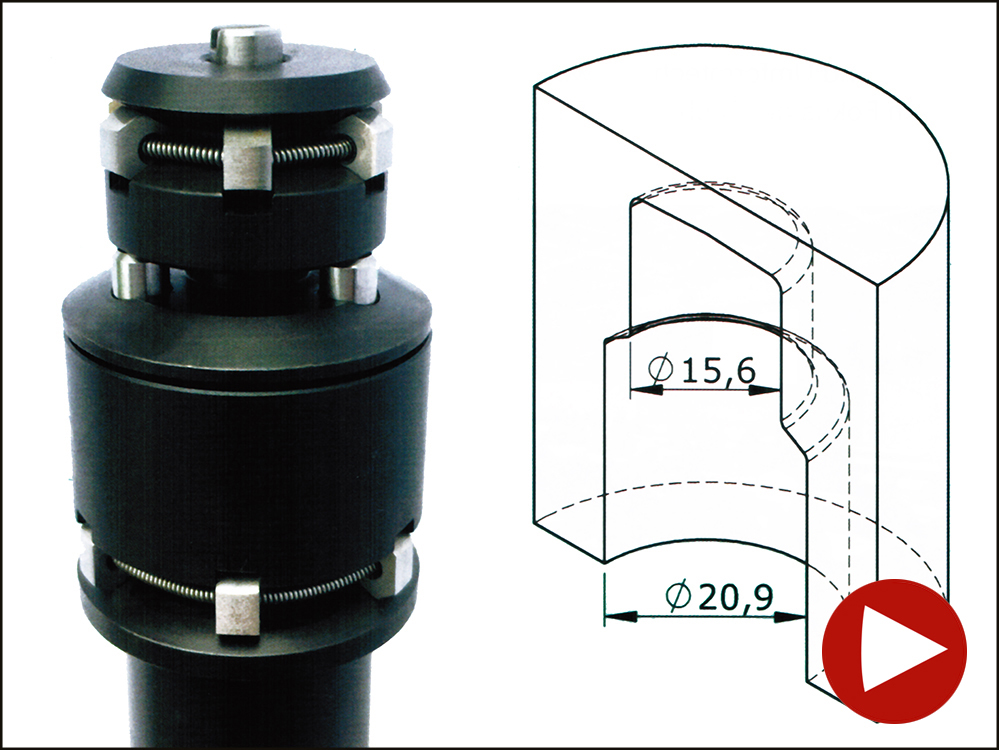

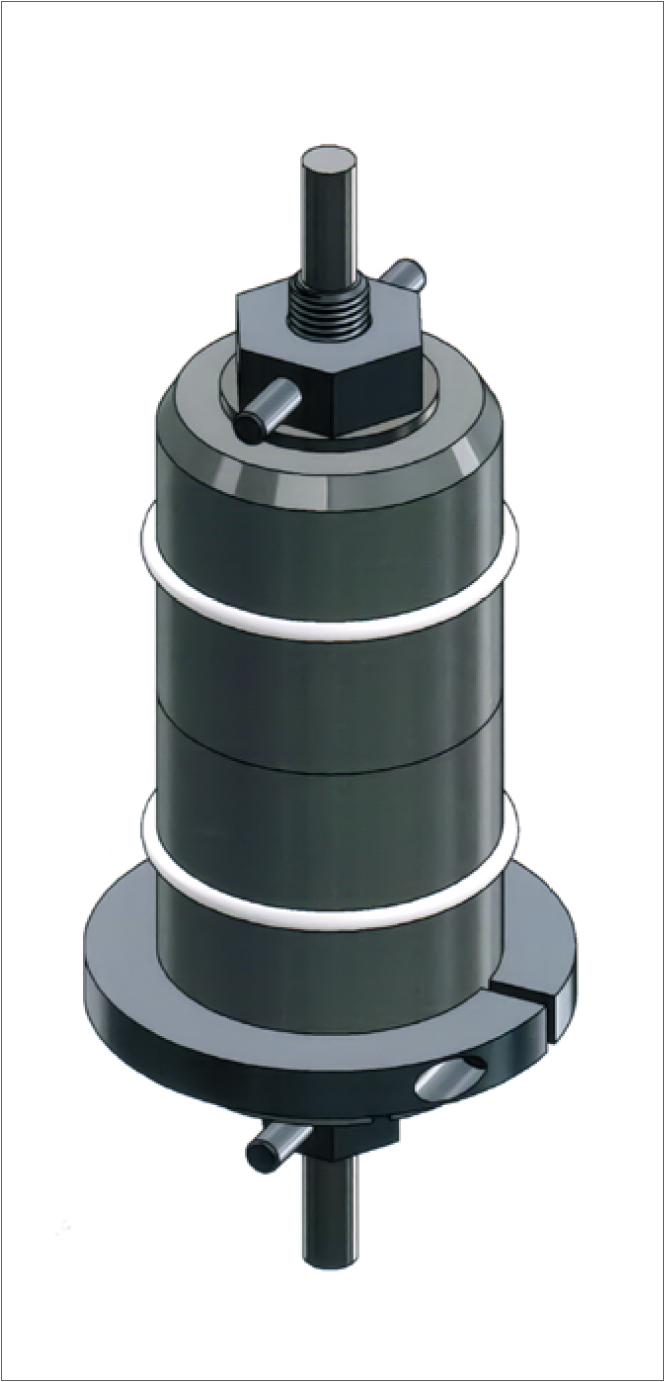

Multi-level centering clamp for turning and grinding

For both automatic and manual clamping

Benefits:

- Varying diameters

- Floating clamping levels

- Two or any number of clamping levels

- Precise self-centering

- Stable connection

- Distortion-free positioning and clamping

- Generous clamping range

- Minimizes tolerances by positioning and clamping at the zero point

- Customized height

Material:

Body: 1.2842, hardened and burnished

Ball/segment: 1.4112, hardened and ground

Tension spring: 1.4210 (VA)

Applications:

Friction-locked clamping for grinding, turning, welding, etc. Automated or manual clamping. With segments (standard) to protect the workpiece or with balls, e.g. for tapered and cast workpieces. Segments and balls can be combined. The high level of stability allows for vibration-free all-around machining without any supplementary tension.

(please click on the table to enlarge)

Q = number of segments

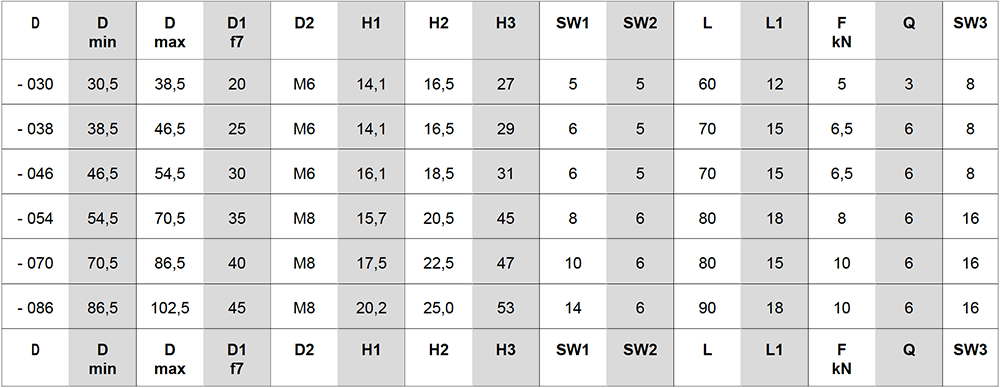

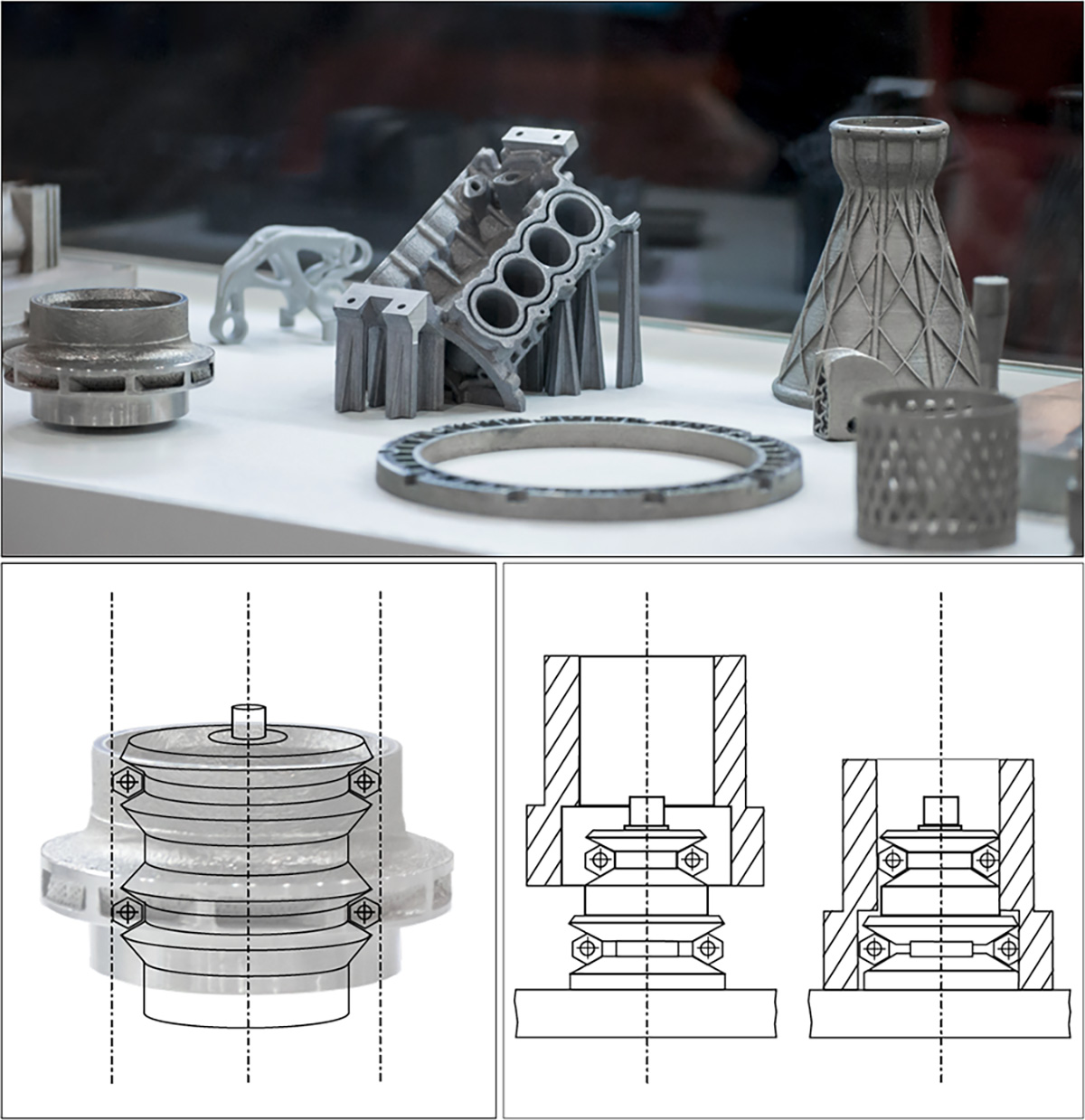

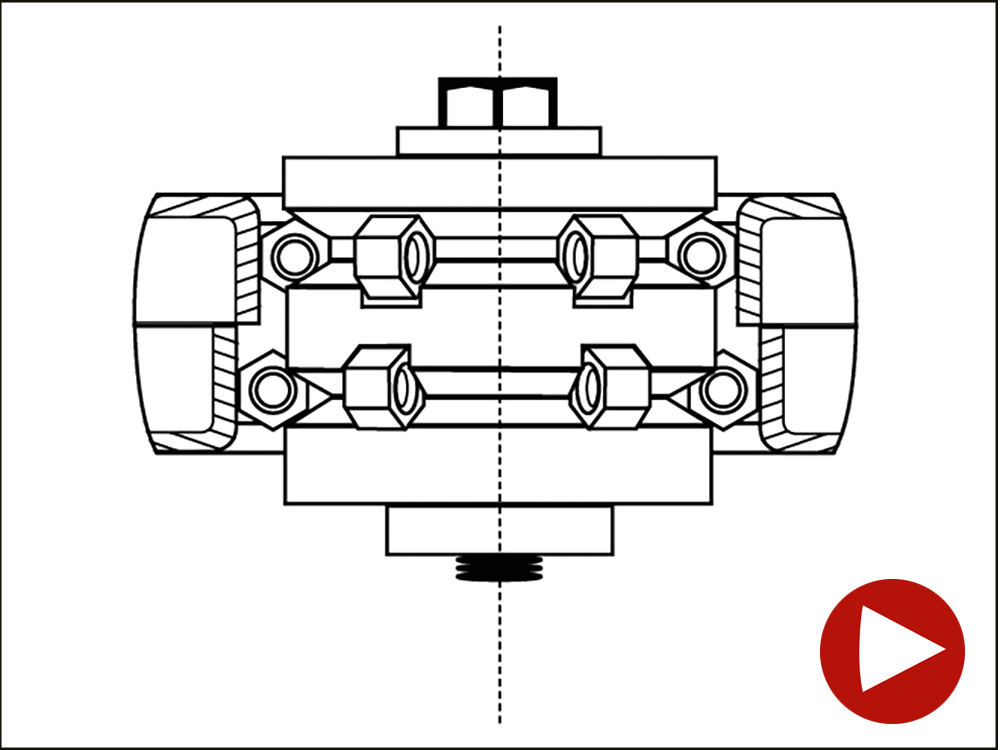

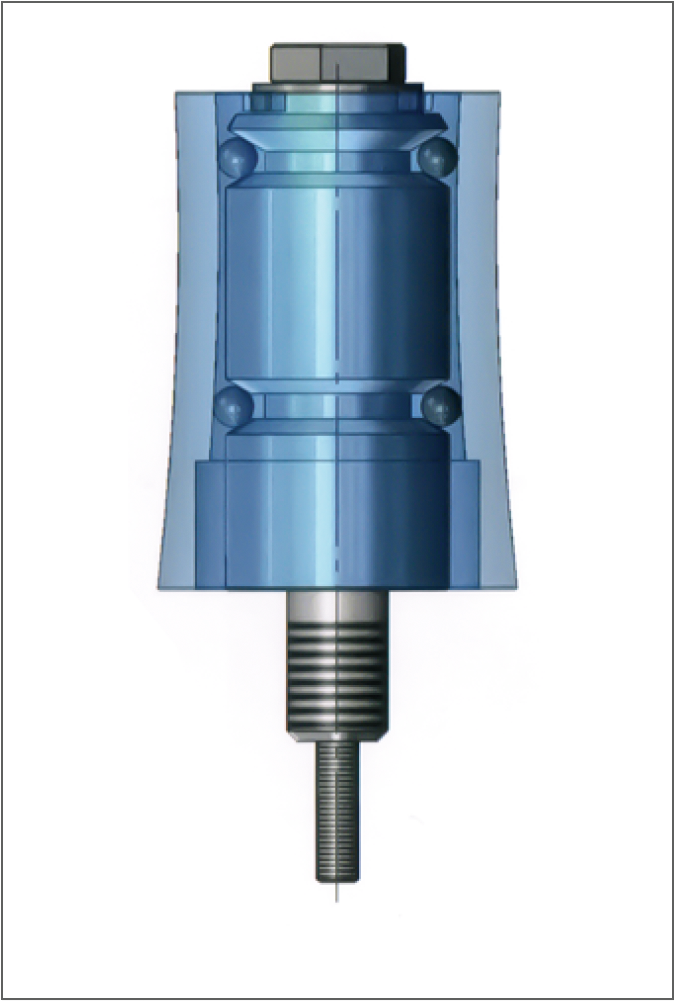

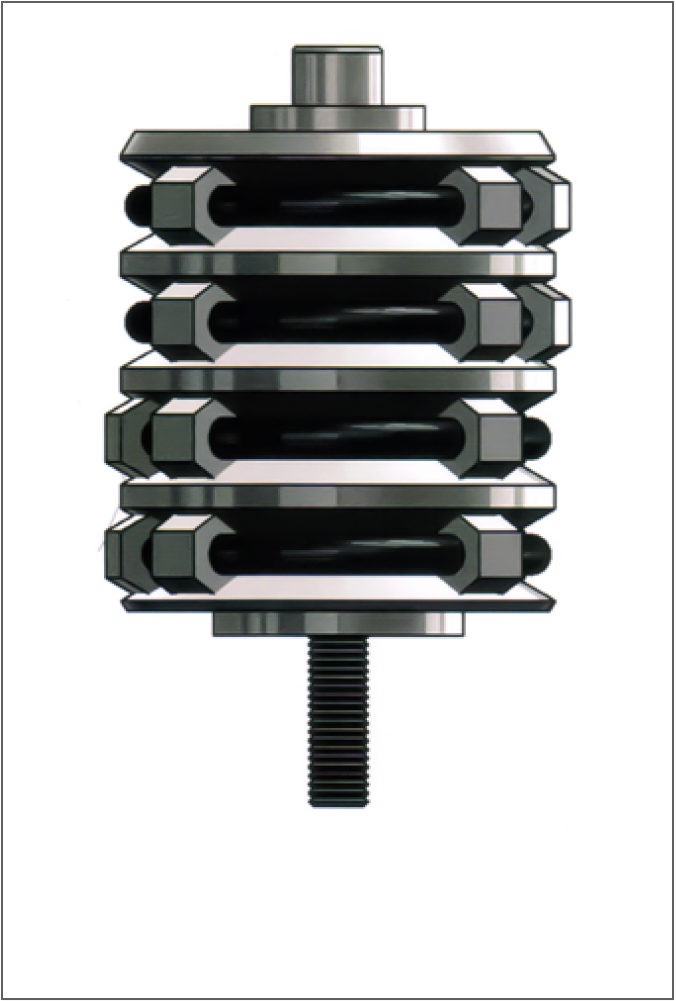

Multi-level internal clamp

For both automatic and manual clamping

Applications:

Additively manufactured components can be effectively reworked using a multi-level internal clamp for milling and turning.

With segments (standard) to protect the work piece or with balls, e.g. for tapered and additively manufactured workpieces. Segments and balls can be combined. The high level of stability allows for vibration-free all-around machining without additional supplementary tension.

Benefits:

- Varying diameters

- Floating clamping levels

- Two or any number of clamping levels

- Precise self-centering

- Stable connection

- Distortion-free positioning and clamping

- Generous clamping range

- Minimizes tolerances by positioning and clamping at the zero point

- Customized height according to customer’s dimensions

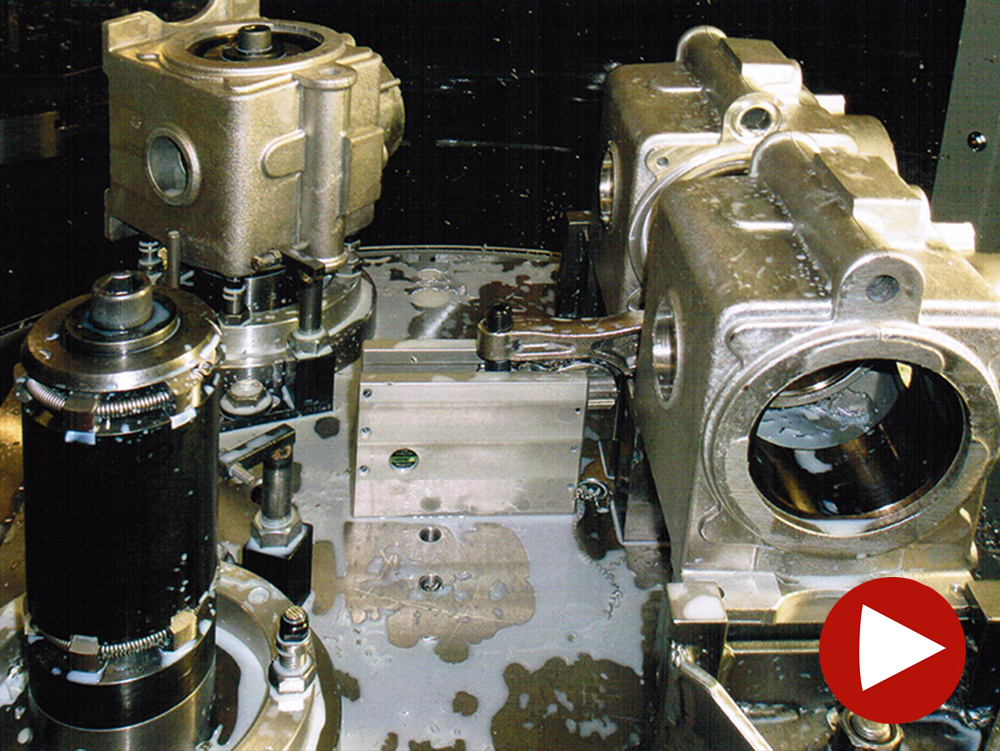

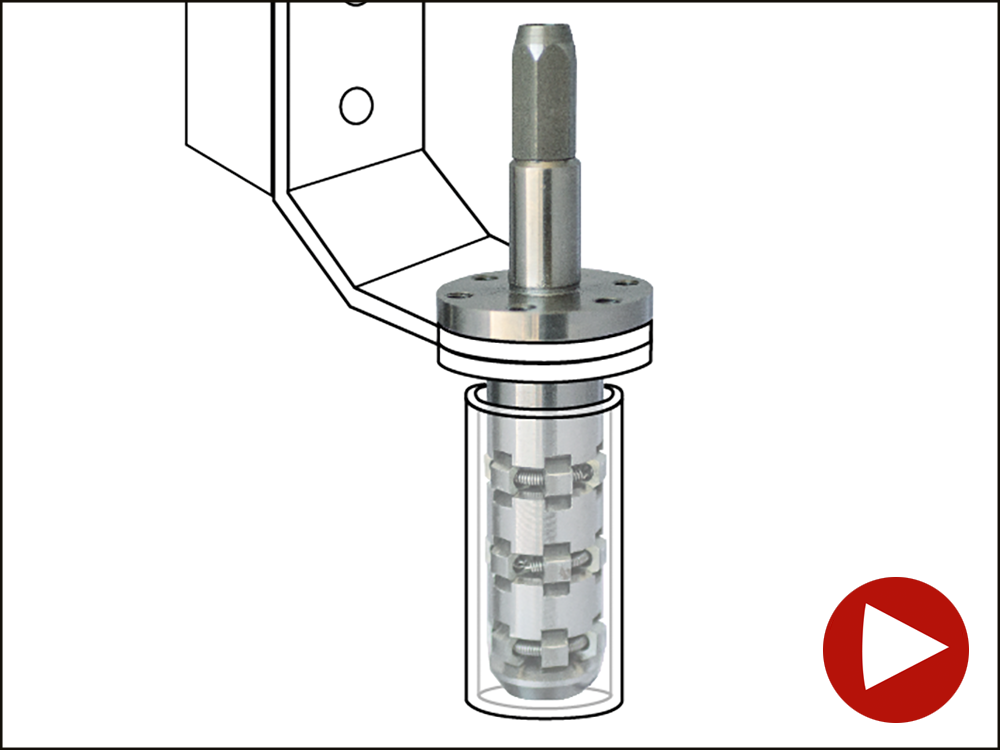

Customer-specific designs

Machining a cast aluminum piece with a pre-drilled inner bore hole, using a barrier-free all-around machining process.

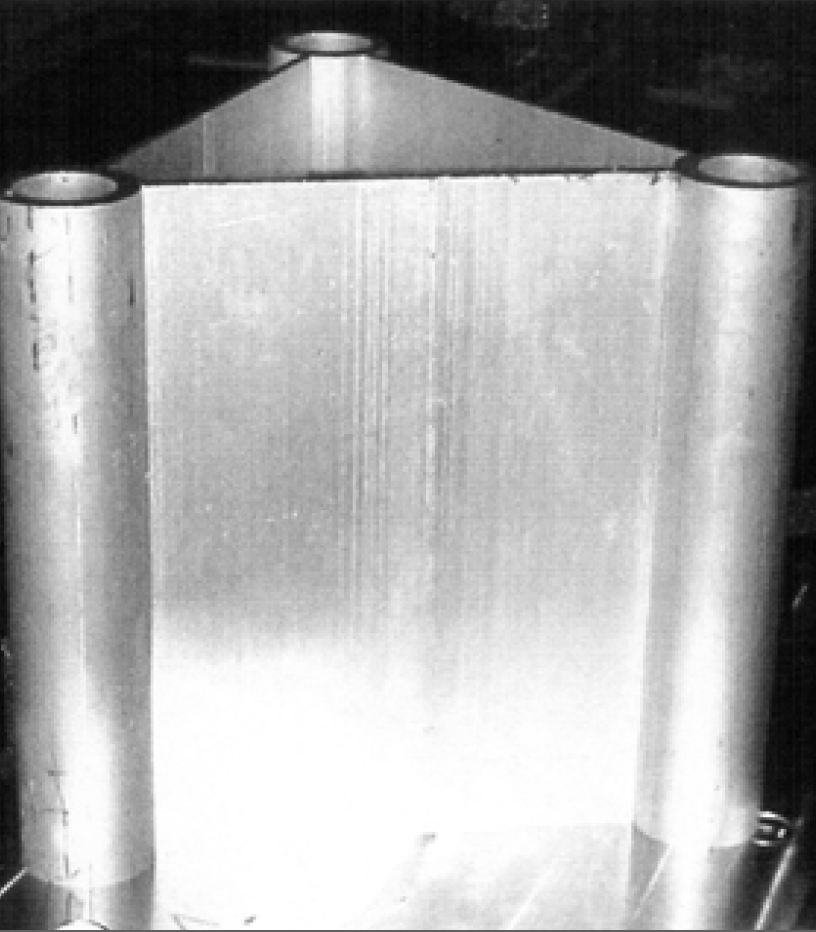

Simultaneously machining both sides of aluminum tubes with varying internal diameters.

All-around machining of an aluminum cube that needs to be clamped from the inside.

The exterior of a hot-punch component needs to be automatically machined on a turning lathe in large quantities.

Two stamped, mirror-image half shells need to be aligned precisely with one another

Securely hold bicycle frames on an assembly line (500 N holding force) and prevent them from rotating.

Further examples customized special constructions

We work on the basis of our products and experience the solution for your clamping task. Target-oriented, we focus on working closely with you to your project.

For non-positive clamping in the casting

For clamping in thin-walled plastic parts

With a floating plate for positioning and clamping heavy metal sheets

For automatic assembly by robots

In special sizes, here with Ø 214 mm

As a ball printing tool for bead embossing

Clamping device for a milling operation in three predefined holes of a

drawn aluminium profile (Picture 1)

Clamping device for a milling operation in three predefined holes of a

drawn aluminium profile (Picture 2)

Further examples patented versatility

Only a few clamping systems can be used as variably and handled as easily as our multi-level internal clamp. As soon as a workpiece has a bore of at least 12 mm in diameter, the economic efficiency of this flexible clamping solution can hardly be beaten. The multi-level internal clamp can be operated manually or fully automatically, centres itself and offers maximum precision with minimum set-up time.

Contact

Reis InnenSpannung GmbH

Steinstraße 6

D-61440 Oberursel

Represented by:

Dieter Reis

Fon: +49 6171 287 3663

Fax: +49 6171 287 3669